About the Process

Sulfuric anodizing is a process that provides a conversion on aluminum which changes the surface of the material to a naturally occurring aluminum oxide.

The oxide build-up changes the surface of the aluminum which then provides greater abrasion resistance as well as increased corrosion protection (roughly 336 hours per ASTM B117). The finish from sulfuric anodizing will not only build up the aluminum oxide on the surface 0.0002" - 0.0003" thick, but will also penetrate into the material the same amount.

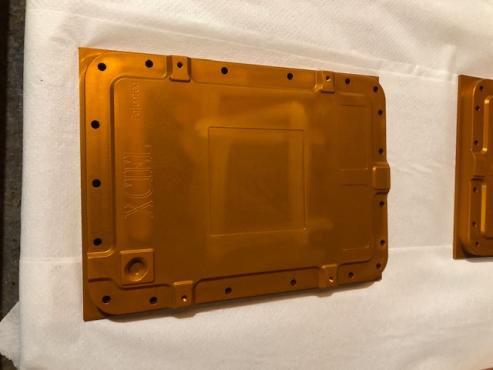

Other than a clear anodize this coating may also be dyed in various colors. The typical industry colors include black, clear, green, gold, red, and blue. One other interesting property of aluminum oxide is that it is a great electrical insulator.

If you are in need of a long part anodized we have some of the longest tanks in Houston! Request a quote for MIL-A-8625 and MIL-PRF-8625 sulfuric acid anodize today.

Specifications:

- MIL-A-8625F

- MIL-PRF-8625

Colors:

- Black

- Clear

- Gold

- Green

- Blue

- Red

MIL-A-8625, MIL-PRF-8625 Type II: Sulfuric Acid Anodizing

Base Materials that MIL-A-8625 anodize type II sulfuric anodizing can be applied include 1100, 2000, 3000, 5000, 6000, and 7000 series aluminum alloys.

- Class 1: Specifies that there will be no dye applied to the finished part

- Class 2: Specifies that there will be a dye applied to the finished part

MIL-SPEC Coatings

We provide metal finishing services for most MIL-SPEC coatings. All finished parts are inspected by our quality control center to make sure the highest standards are met.

Frequently Asked Questions

The answer is no! Hard anodize is a much thicker and abrasion resistant coating compared to sulfuric anodizing.

The answer is yes; however, it must be noted that stripping the anodic coating will cause some loss in the base material.

The answer is no, the part being anodized must only be aluminum. Anything else will be destroyed in the sulfuric anodizing process.

Questions?

Give us a call or send us a message and our team will contact you as soon as possible.

*denotes a required field.

- 8736 Schumacher Ln

Houston, TX 77063 - Toll-Free: (877) 311-0123

Phone: (713) 785-4955